Plastics are everywhere in modern life. From high-tech products like mobile phones to simple plastic cups, plastic has many uses. Many businesses fabricate their plastic parts or products for any number of applications.

If a business is going to work with plastics in such a way, it will need the right tools or equipment. For many, that will mean selecting the right tool for cutting plastic. Some are simpler machines that people operate manually, and there are even industrial robots for cutting plastics.

Which cutting machine is best for working with plastics? It depends on the type of plastic and the application. This post will look at some of the more common machines used to cut plastics.

Saws

Saws are some of the simpler machines for cutting plastic. An industrial plastic saw will work in a way that is similar to most other saws. You have a cutting blade and a mechanism that moves the blade against the material to cut. Both band and circular saws are common for cutting plastics in industrial settings. Some processes might also benefit from a machine like a wire saw. These large industrial saws might have different features depending on the application. You can also find different blades for making different types of cuts.

Die Cutting

With this fabrication process, the plastic is cut using a custom die. The die is like a preset shape for cutting the plastic. The die is pressed or stamped into a plastic sheet, cutting a shape that resembles the die. This process can be effective for mass-producing a large quality of plastic pieces that are the same shape. Beyond being advantageous for its speed, die-cutting is also popular because it creates parts at lower costs. Similar to using a cookie cutter, die cutting employs steel rule dies to stamp or blank out components. Simple or intricate forms may be cut out of a variety of substances with this method, including foam, rubber, plastics, cork, and more.

Roll Slitting

What happens if you have a large roll of plastic material you need to cut into smaller rolls? This is where roll slitting can be one of the best cutting processes. With roll slitting, you take larger rolls and run them through a machine that pares them down to rolls that are ready for practical applications. It can be used on materials like vinyl, laminates, and tapes. The machines usually have a pair of cutting blades that come together to create precision cuts in the rolled material.

Kiss Cutting

Kiss cutting is a good option for a variety of applications. With kiss cutting, the machine cuts the top layer of material but leaves the bottom layer untouched. The back layer is often a sheet of adhesive paper. The cut is made to the primary material, and the machine leaves the parts or pieces on the adhesive paper. When the part is ready to use, it can be peeled off the paper. Depending on the application, the kiss process can make the parts easier to transport, store or use. Even with thicker materials, waterjet cutting produces products with tight tolerances and clean, precise edges by passing a stream of high-pressure water through a precision nozzle.

Rotary Die Cutting

While it is a type of die cutting, rotary die cutting is very different from the more conventional method of stamping or pressing a die. With rotary die cutting, you have a machine with two cylinders. The first is a cylindrical die that shapes the product, and the other serves as a mandrel. A thin sheet of material can be fed through the machine, and the two work together to create the cuts. Like stamped die cutting, rotary die cutting can be good for quick mass production at lower costs. A machined cylindrical die revolves against a mandrel during rotary die cutting. It enables repeatability and fine precision for thinner gauge materials both with and without pneumatically glue.

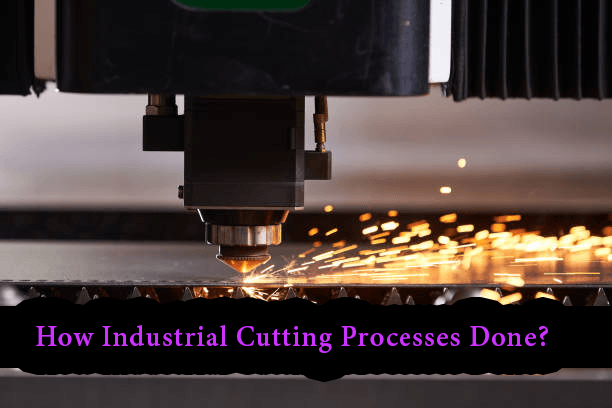

Laser Cutting

With laser cutting, the manufacturing process harnesses the cutting power of concentrated light. Laser cutting has no physical blade that cuts the material, and it all occurs contactless from the energy imparted by a highly-focused laser beam. The primary benefits of laser cutting are the tight tolerances and incredible accuracy. With the right type of machine, you can cut very small but finely detailed parts. These machines can cut through single layers or multiple layers of material. They can also work as an alternative to conventional kiss cutting. By shining a finely focused laser beam onto the material, laser cutting may be used to cut thin gauge plastics, open and closed cell foam, compressed fiber, and adhesives. Kiss-cutting techniques that leave parts on a substrate with an adhesive release layer and individual cut-through parts both benefit from laser cutting.

You will save time and setup costs since the process is computer-controlled and needs little fixturing or equipment. Long production runs and prototypes both employ waterjet cutting. The kinds of materials that waterjets can cut are essentially unrestricted.

Waterjet Cutting

As you may expect, waterjet cutting uses jets of water to make cuts. These machines have precision nozzles that force the water out under incredible pressure. Even beyond plastic, a waterjet machine can cut materials like stone and metal. Waterjet cutting can be incredibly precise and accurate. However, the primary advantage of waterjet cutting is that it is a method for cool cutting. Some materials might scorch, burn or warp from the heat of other cutting processes, and a waterjet avoids this by using water as the cutting instrument. You will save time and setup costs since the process is computer-controlled and needs little fixturing or equipment. Long production runs and prototypes both employ waterjet cutting. The kinds of materials that waterjets can cut are essentially unrestricted.

The last step of production helps mould components have a better surface polish, aesthetics, dimensional integrity, and tolerance when they come out of the press.

These are just a few more common ways to cut plastics in an industrial setting. Many of them can also be used to cut materials besides plastics. When selecting the right tool, you need to consider the material you are cutting, the application, and the level of precision.

Also Read: